| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

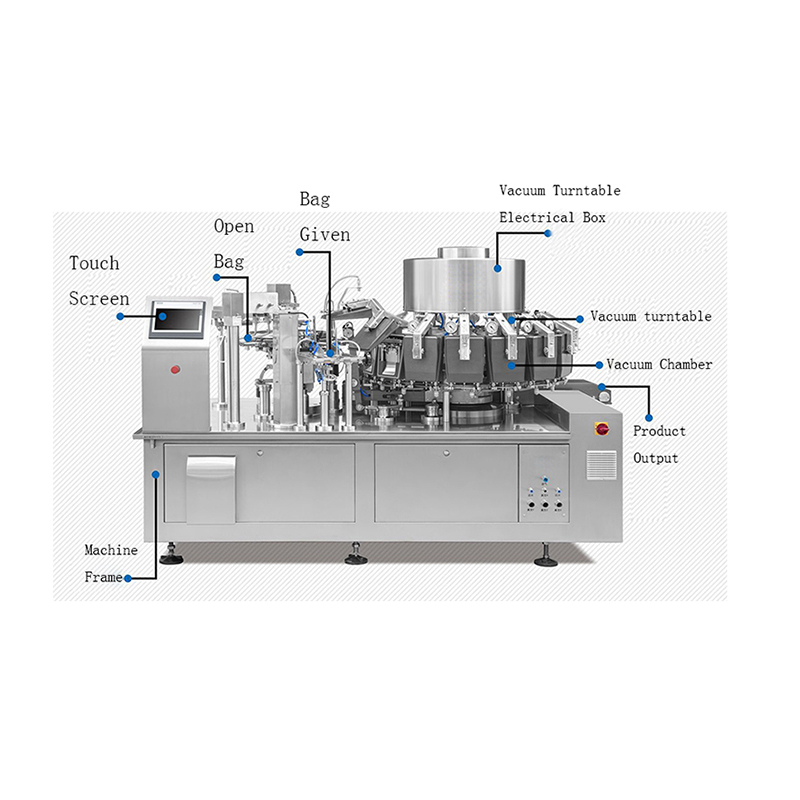

Machine Features:

1. High-Speed Rotary Packaging System

Intermittent rotation in the filling zone and continuous rotation in the vacuum zone ensure smooth, stable, and efficient operation—up to 100 bags/min.

2. Wide Bag Size Compatibility

Supports multiple bag widths and lengths; zipper bag speed up to 40 packs/min. Ideal for stand-up bags, flat bags, zip bags, and vacuum bags.

3. Motorized Adjustable Grippers

Bag clamps in the filling area adjust automatically with a motor, improving changeover speed and reducing downtime.

4. Full 304 Stainless Steel Structure

Machine body and main components are stainless steel—durable, hygienic, and suitable for food processing.

5. Washable Filling and Vacuum Chambers

All filling zones and vacuum chambers are fully washable for easy cleaning and strict hygiene control.

6. Compatible With Multiple Dosing Systems

Supports granular weigher, powder screw filler, liquid & paste pump, meat filling systems, and other dosing solutions.

7. Easy Control & Monitoring

Features micro-computer control, touch-screen interface, and transparent vacuum chamber lids for real-time monitoring.

8. Customizable Solutions Available

Bag size, filling system, vacuum chamber, and machine configuration can be customized based on your production needs.

Products Specification:

| Model | MR8-120ZK/MR8-200ZK/MR-160ZK |

| Bag Size | Width:70-120mm/120-200mm, Length:80-160mm/150-300mm |

| Filling Volume | 10-500g (Depending on type of products) |

| Capacity | 30-100bags/min (The speed depends on type of products and packaging material used) |

| The highest can be 100 packs / minute | |

| Zipper Bag The heghest can be 40packs/minute | |

| Package Accuracy | Error≤±1% |

| Total Power | 2.5KW/5.5kw (220V/380V,3PH,50HZ) |

| Demension | 2100*1400*1700 mm/2600*1900*1700(Length*Width*Height) |

| Weight | 1600KGS/3000kgs |

| Compress Air Requirement | ≥0.8m³/min supply by user |

Products Pictures:

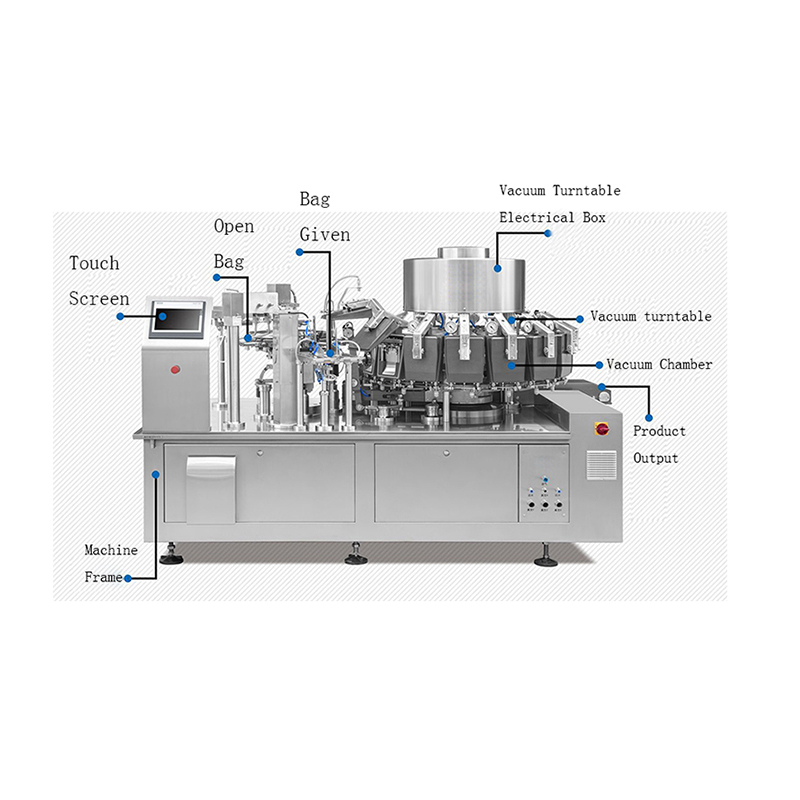

Machine Features:

1. High-Speed Rotary Packaging System

Intermittent rotation in the filling zone and continuous rotation in the vacuum zone ensure smooth, stable, and efficient operation—up to 100 bags/min.

2. Wide Bag Size Compatibility

Supports multiple bag widths and lengths; zipper bag speed up to 40 packs/min. Ideal for stand-up bags, flat bags, zip bags, and vacuum bags.

3. Motorized Adjustable Grippers

Bag clamps in the filling area adjust automatically with a motor, improving changeover speed and reducing downtime.

4. Full 304 Stainless Steel Structure

Machine body and main components are stainless steel—durable, hygienic, and suitable for food processing.

5. Washable Filling and Vacuum Chambers

All filling zones and vacuum chambers are fully washable for easy cleaning and strict hygiene control.

6. Compatible With Multiple Dosing Systems

Supports granular weigher, powder screw filler, liquid & paste pump, meat filling systems, and other dosing solutions.

7. Easy Control & Monitoring

Features micro-computer control, touch-screen interface, and transparent vacuum chamber lids for real-time monitoring.

8. Customizable Solutions Available

Bag size, filling system, vacuum chamber, and machine configuration can be customized based on your production needs.

Products Specification:

| Model | MR8-120ZK/MR8-200ZK/MR-160ZK |

| Bag Size | Width:70-120mm/120-200mm, Length:80-160mm/150-300mm |

| Filling Volume | 10-500g (Depending on type of products) |

| Capacity | 30-100bags/min (The speed depends on type of products and packaging material used) |

| The highest can be 100 packs / minute | |

| Zipper Bag The heghest can be 40packs/minute | |

| Package Accuracy | Error≤±1% |

| Total Power | 2.5KW/5.5kw (220V/380V,3PH,50HZ) |

| Demension | 2100*1400*1700 mm/2600*1900*1700(Length*Width*Height) |

| Weight | 1600KGS/3000kgs |

| Compress Air Requirement | ≥0.8m³/min supply by user |

Products Pictures: