| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

Machine Features:

1. High-Efficiency Live-Line Operation

Performs insulation coating without power shutdown, reducing grid outage time.

One operator can control 2–3 robots simultaneously, enabling large-scale maintenance.

2. Enhanced Safety & Zero Aerial Work

Fully ground-based operation eliminates manual climbing risks.

Designed to improve power line maintenance safety standards.

3. Intelligent Precision Coating

Auto-detection of conductor diameter (optional module) for uniform coating.

Slope-adaptive press wheels maintain coating stability on inclined lines.

Full-process visual monitoring for real-time operation control.

4. Strong Adaptability Across Scenarios

Supports multiple conductor specifications (6.9–25.2 mm across series models).

Lightweight design (<20 kg) reduces load on power lines and allows easy deployment.

5. Long Endurance for Continuous Operations

≥4 hours of runtime supports extended projects without frequent interruptions.

Modular structure and replaceable batteries simplify maintenance.

6. Cost Reduction & Operational Savings

Reduces labor intensity and minimizes safety-related costs.

Live-line capability prevents economic losses caused by power outages.

Products Specification:

| Item | Specification |

| Applicable Conductor Specs | LGJ35/6 ~ LGJ185/30(Wire Ø 8.16–19 mm) |

| Unloaded Weight | ≤20 kg |

| Maximum Loading Capacity | 4 L |

| Coating Thickness | 1–5 mm |

| Running Speed | ≤8 m/min |

| Gradeability | ≤25° |

| Battery Life | ≥4 hours |

| Maximum Working Height | ≤19 m |

| Equipment Dimensions | 960 × 285 × 450 mm |

| Package Size | 680 × 285 × 380 mm |

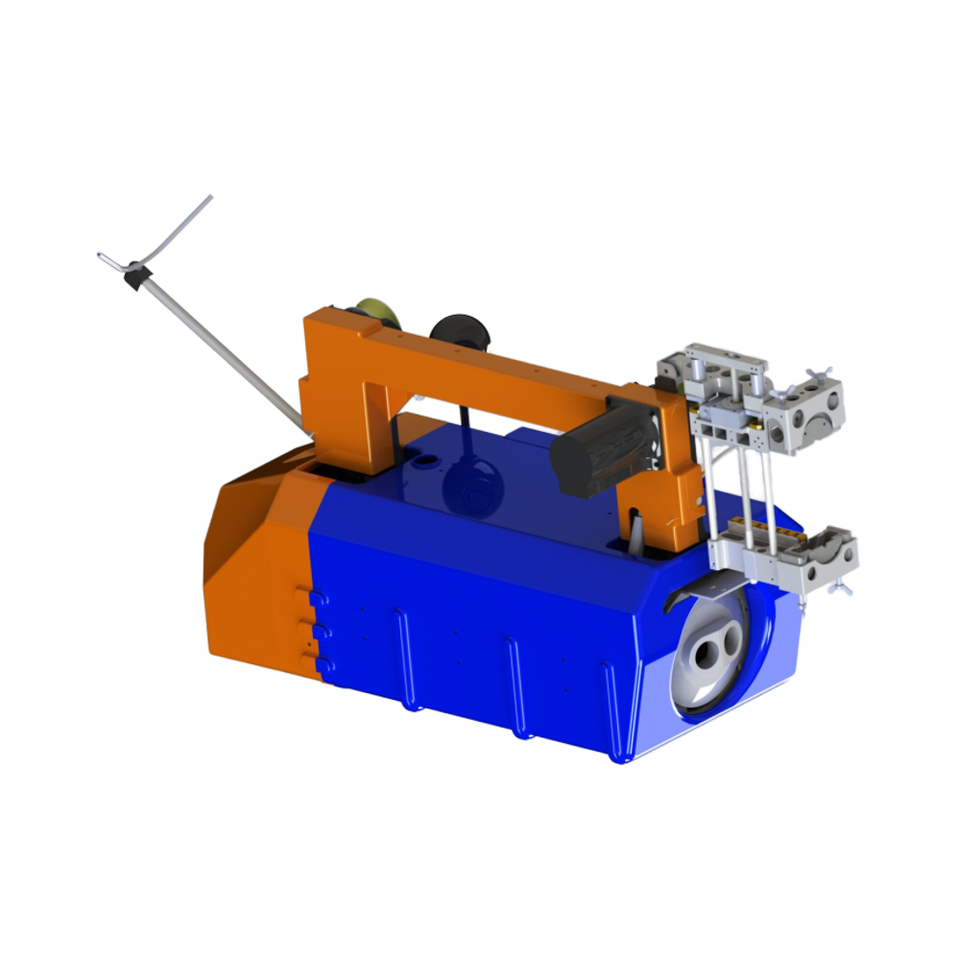

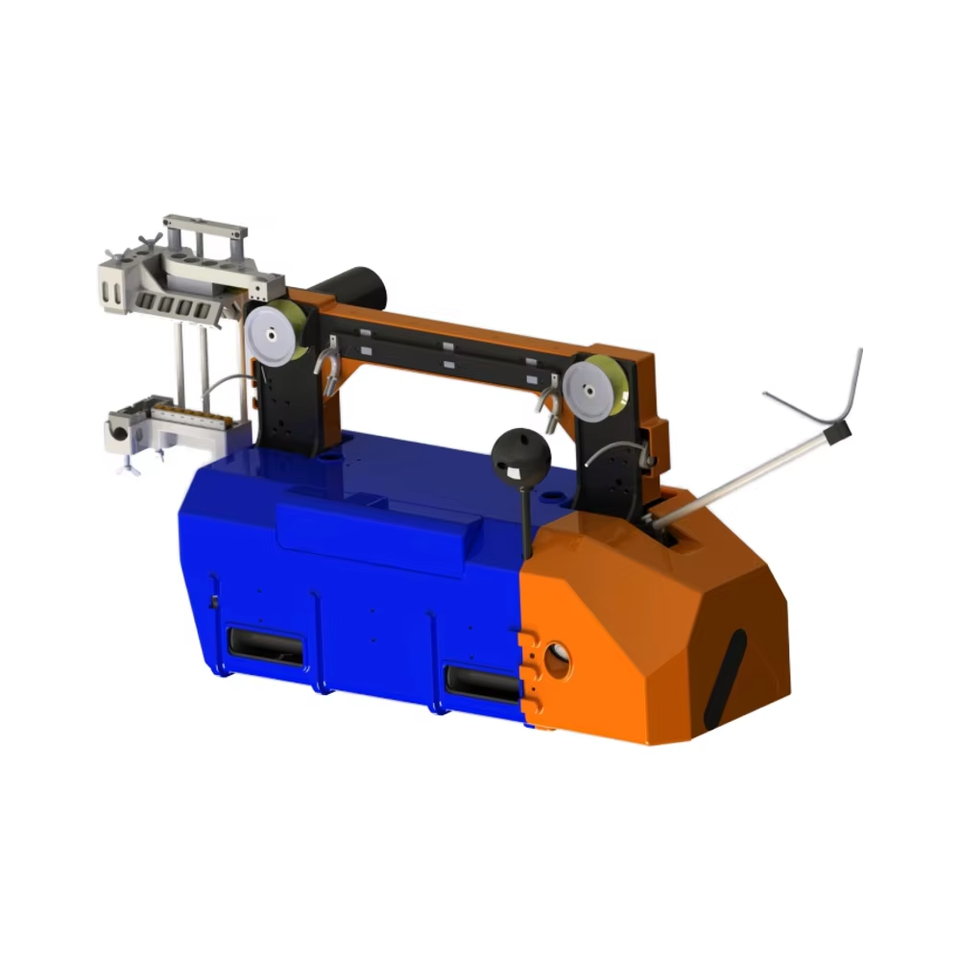

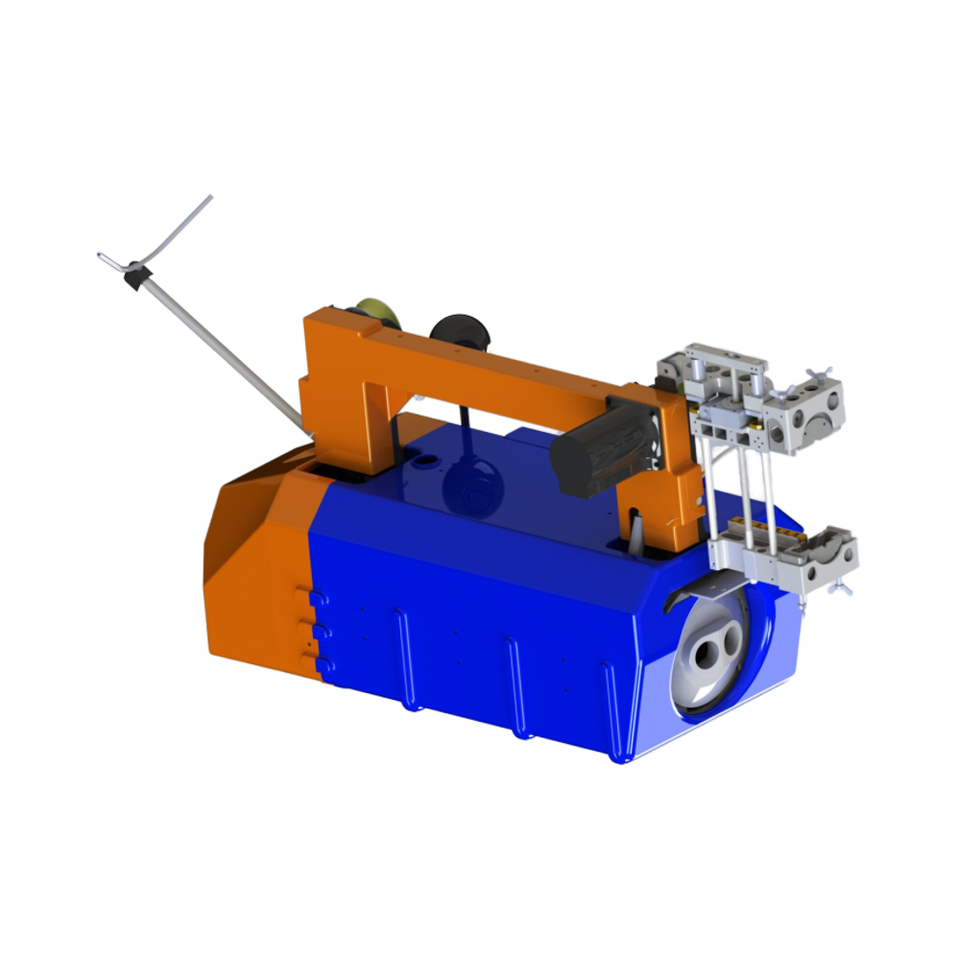

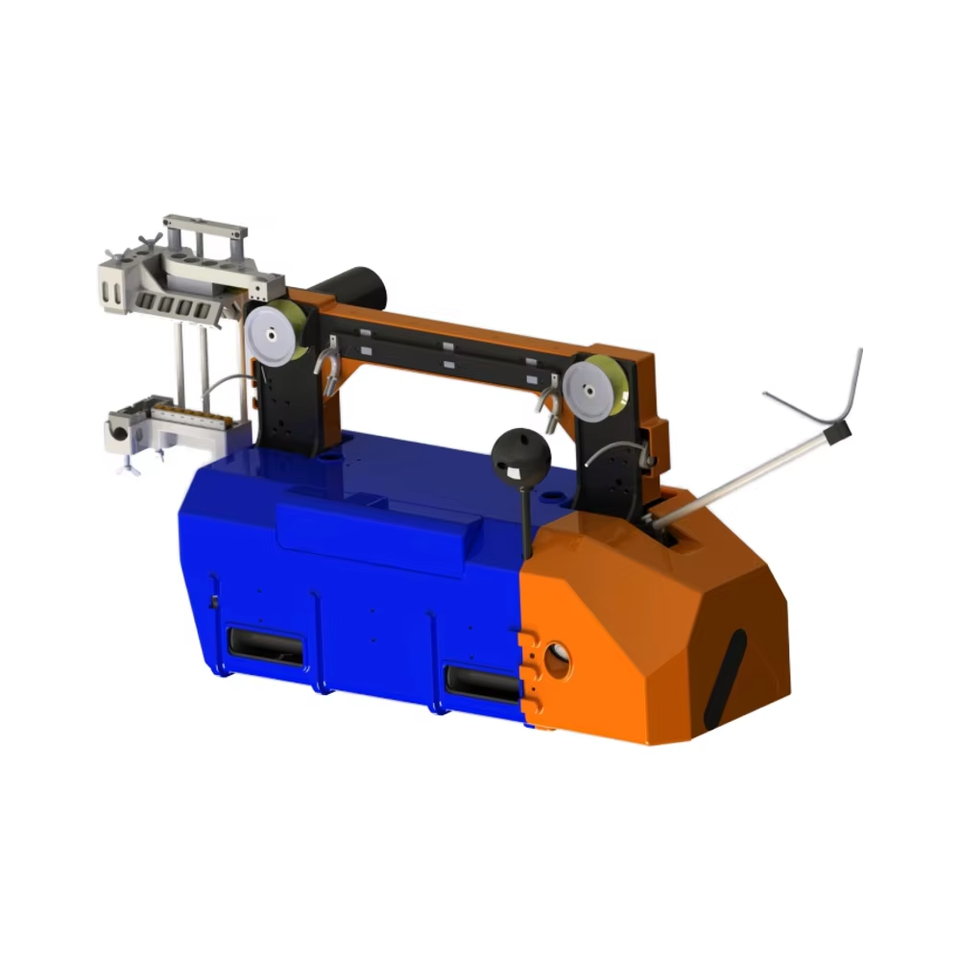

Products Pictures:

Machine Features:

1. High-Efficiency Live-Line Operation

Performs insulation coating without power shutdown, reducing grid outage time.

One operator can control 2–3 robots simultaneously, enabling large-scale maintenance.

2. Enhanced Safety & Zero Aerial Work

Fully ground-based operation eliminates manual climbing risks.

Designed to improve power line maintenance safety standards.

3. Intelligent Precision Coating

Auto-detection of conductor diameter (optional module) for uniform coating.

Slope-adaptive press wheels maintain coating stability on inclined lines.

Full-process visual monitoring for real-time operation control.

4. Strong Adaptability Across Scenarios

Supports multiple conductor specifications (6.9–25.2 mm across series models).

Lightweight design (<20 kg) reduces load on power lines and allows easy deployment.

5. Long Endurance for Continuous Operations

≥4 hours of runtime supports extended projects without frequent interruptions.

Modular structure and replaceable batteries simplify maintenance.

6. Cost Reduction & Operational Savings

Reduces labor intensity and minimizes safety-related costs.

Live-line capability prevents economic losses caused by power outages.

Products Specification:

| Item | Specification |

| Applicable Conductor Specs | LGJ35/6 ~ LGJ185/30(Wire Ø 8.16–19 mm) |

| Unloaded Weight | ≤20 kg |

| Maximum Loading Capacity | 4 L |

| Coating Thickness | 1–5 mm |

| Running Speed | ≤8 m/min |

| Gradeability | ≤25° |

| Battery Life | ≥4 hours |

| Maximum Working Height | ≤19 m |

| Equipment Dimensions | 960 × 285 × 450 mm |

| Package Size | 680 × 285 × 380 mm |

Products Pictures: