| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

Machine Features:

1. High Efficiency & Convenience

The robot performs insulation coating without power interruption, ensuring stable power delivery. Remote ground control eliminates aerial work, and a single controller can manage multiple robots simultaneously to increase productivity.

2. Safety & Reliability

It removes the need for manual high-altitude climbing, significantly reducing operational risks and improving worker safety during live-line maintenance.

3. Precision & Intelligence

Equipped with optional wire-diameter measurement for automatic parameter calibration, ensuring uniform coating thickness. Slope-adaptive pressing wheels and real-time video monitoring improve stability and process accuracy.

4. Flexibility & Adaptability

Supports a wide wire diameter range and offers lightweight design for easier transport and deployment in complex terrain. Multiple model variants cover full operational scenarios.

5. Long Endurance & Low Maintenance

The ≥4-hour runtime enables continuous large-scale operations. Its modular components support fast maintenance and easy battery replacement to minimize downtime.

Products Specification:

| Item | Details |

| Model Structure | Dual material cylinders (Ø125mm), left–right mold closing |

| Functional Configuration | Hook-on indicator, HD video (2 channels), multi-speed adjustment, remote assistance |

| Applicable Conductor Range | LGJ25/8 ~ LGJ250/40 (wire diameter 8.16–22.4 mm) |

| Unloaded Weight | ≤25 kg |

| Maximum Material Capacity | 8 L (4 L × 2 cylinders) |

| Coating Thickness | 1–6 mm |

| Running Speed | ≤10 m/min |

| Gradeability | ≤30° |

| Battery Life | ≥4 hours |

| Equipment Dimensions | 900 × 425 × 820 mm |

| Packaged Dimensions | 700 × 425 × 310 mm |

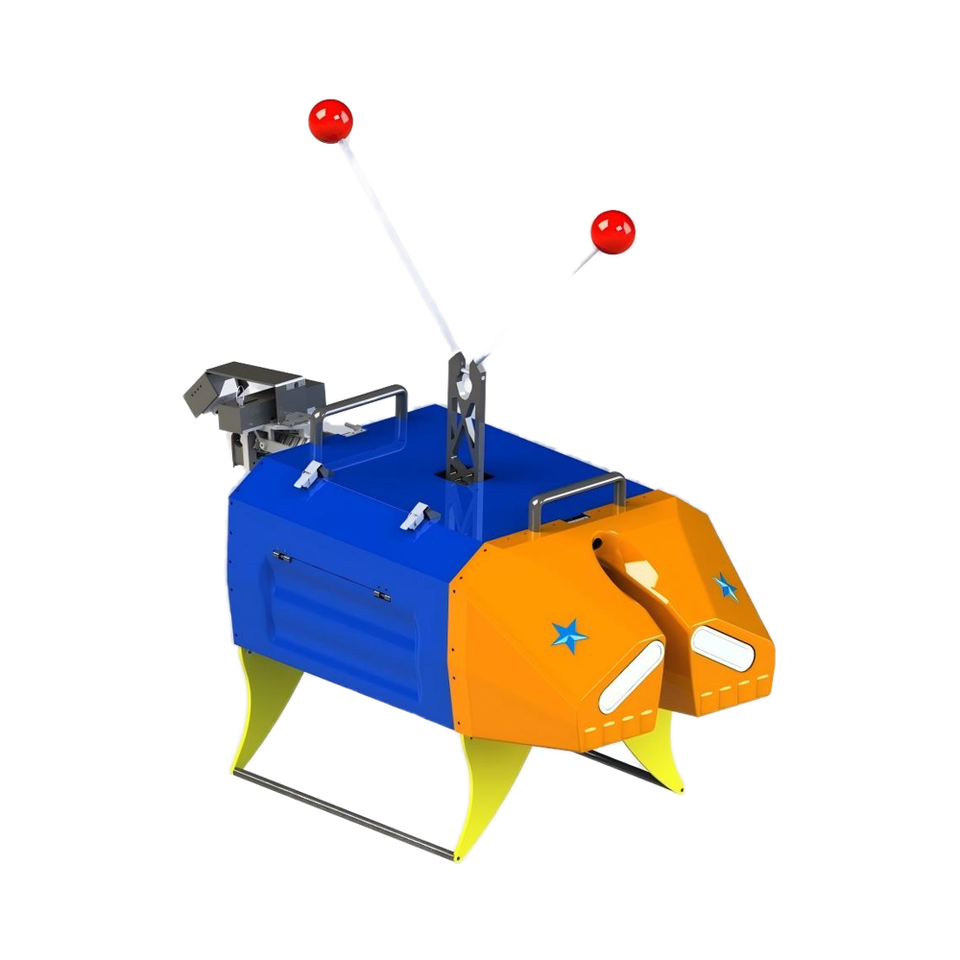

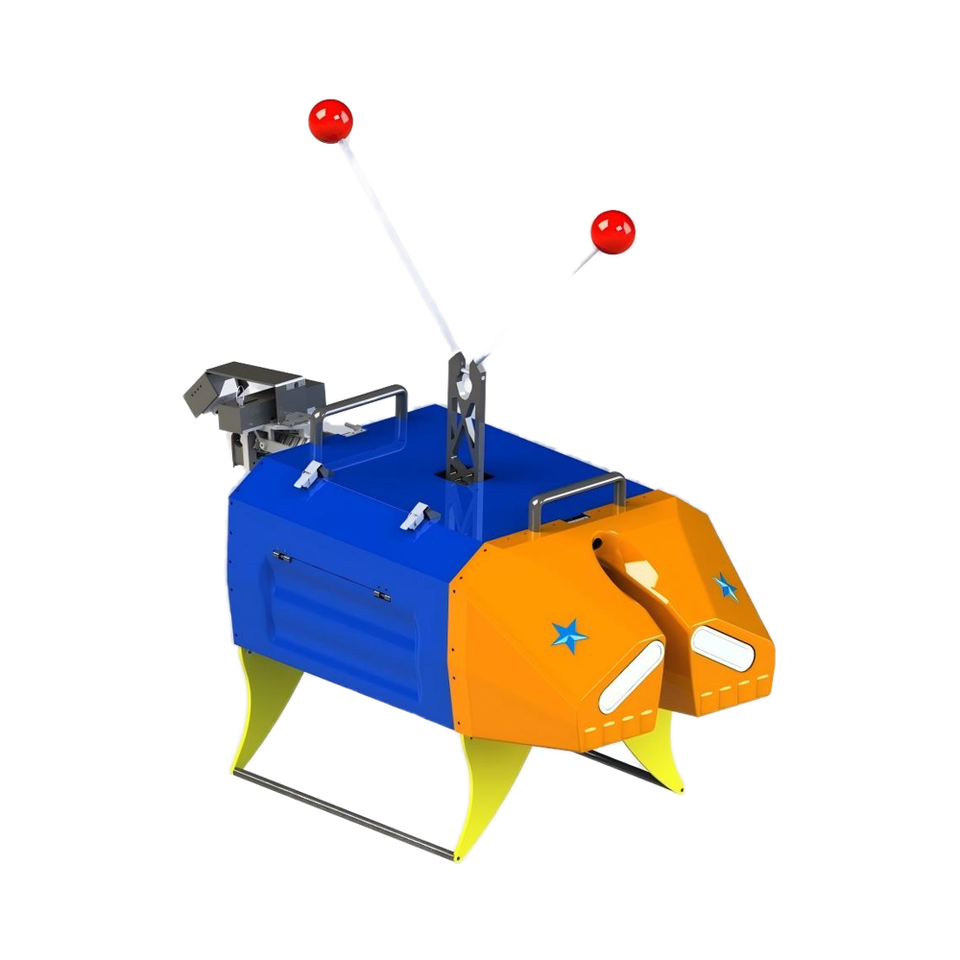

Products Pictures:

Machine Features:

1. High Efficiency & Convenience

The robot performs insulation coating without power interruption, ensuring stable power delivery. Remote ground control eliminates aerial work, and a single controller can manage multiple robots simultaneously to increase productivity.

2. Safety & Reliability

It removes the need for manual high-altitude climbing, significantly reducing operational risks and improving worker safety during live-line maintenance.

3. Precision & Intelligence

Equipped with optional wire-diameter measurement for automatic parameter calibration, ensuring uniform coating thickness. Slope-adaptive pressing wheels and real-time video monitoring improve stability and process accuracy.

4. Flexibility & Adaptability

Supports a wide wire diameter range and offers lightweight design for easier transport and deployment in complex terrain. Multiple model variants cover full operational scenarios.

5. Long Endurance & Low Maintenance

The ≥4-hour runtime enables continuous large-scale operations. Its modular components support fast maintenance and easy battery replacement to minimize downtime.

Products Specification:

| Item | Details |

| Model Structure | Dual material cylinders (Ø125mm), left–right mold closing |

| Functional Configuration | Hook-on indicator, HD video (2 channels), multi-speed adjustment, remote assistance |

| Applicable Conductor Range | LGJ25/8 ~ LGJ250/40 (wire diameter 8.16–22.4 mm) |

| Unloaded Weight | ≤25 kg |

| Maximum Material Capacity | 8 L (4 L × 2 cylinders) |

| Coating Thickness | 1–6 mm |

| Running Speed | ≤10 m/min |

| Gradeability | ≤30° |

| Battery Life | ≥4 hours |

| Equipment Dimensions | 900 × 425 × 820 mm |

| Packaged Dimensions | 700 × 425 × 310 mm |

Products Pictures: