| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

Machine Features:

Hybrid 3D Inspection Technology:

Combines stop-and-go imaging and dynamic scanning to optimize inspection speed and precision for different PCB types.

High-Speed In-Line Operation:

Supports real-time inspection on SMT production lines, ensuring minimal cycle time impact and improved throughput.

Comprehensive Defect Detection:

Accurately identifies solder defects, missing components, polarity issues, height deviations, and coplanarity errors.

Flexible Inspection Modes:

Inspection approach can be switched based on product needs—ideal for high-mix or high-volume manufacturing.

Stable Architecture with Industrial Components:

Built with PLC-driven control, precision engines and bearings to ensure long-term reliability and consistent performance.

User-Friendly Operation:

Supports easy setup, visual debugging, automatic parameter optimization, and seamless integration into automated lines.

Products Specification:

| Item | Specification |

| Product Name | 3D In-line Automated Optical Hybrid Inspection Machine |

| Machine Type | Automated Optical Inspection (AOI) |

| Application | SMT PCB Assembly / Automation Equipment |

| Function | 3D Optical Inspection, Hybrid Imaging |

| Working Mode | Automatic In-line |

| Core Components | PLC, Engine, Bearing |

| Warranty | 1 Year |

| Voltage | 220V |

| Power Consumption | 10 kW |

| Inspection Model | TR7700 SII Plus (model reference without brand attribution) |

| Usage | SMT placement and pick-line inspection |

| Condition | New |

| Package | Wooden Case |

| Video Inspection Report | Provided |

| Machinery Test Report | Provided |

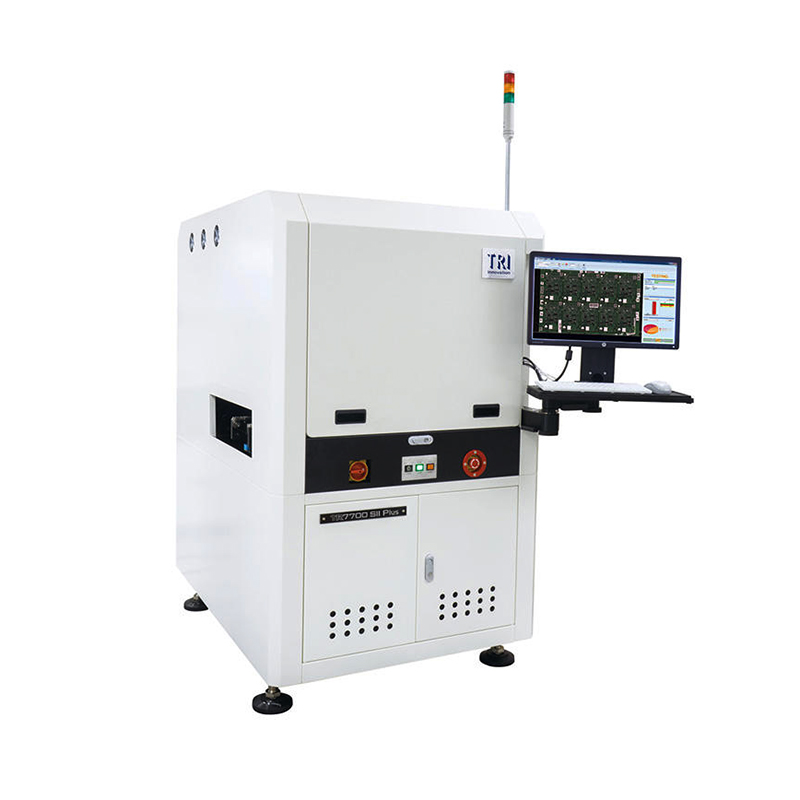

Products Pictures:

Machine Features:

Hybrid 3D Inspection Technology:

Combines stop-and-go imaging and dynamic scanning to optimize inspection speed and precision for different PCB types.

High-Speed In-Line Operation:

Supports real-time inspection on SMT production lines, ensuring minimal cycle time impact and improved throughput.

Comprehensive Defect Detection:

Accurately identifies solder defects, missing components, polarity issues, height deviations, and coplanarity errors.

Flexible Inspection Modes:

Inspection approach can be switched based on product needs—ideal for high-mix or high-volume manufacturing.

Stable Architecture with Industrial Components:

Built with PLC-driven control, precision engines and bearings to ensure long-term reliability and consistent performance.

User-Friendly Operation:

Supports easy setup, visual debugging, automatic parameter optimization, and seamless integration into automated lines.

Products Specification:

| Item | Specification |

| Product Name | 3D In-line Automated Optical Hybrid Inspection Machine |

| Machine Type | Automated Optical Inspection (AOI) |

| Application | SMT PCB Assembly / Automation Equipment |

| Function | 3D Optical Inspection, Hybrid Imaging |

| Working Mode | Automatic In-line |

| Core Components | PLC, Engine, Bearing |

| Warranty | 1 Year |

| Voltage | 220V |

| Power Consumption | 10 kW |

| Inspection Model | TR7700 SII Plus (model reference without brand attribution) |

| Usage | SMT placement and pick-line inspection |

| Condition | New |

| Package | Wooden Case |

| Video Inspection Report | Provided |

| Machinery Test Report | Provided |

Products Pictures: