| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

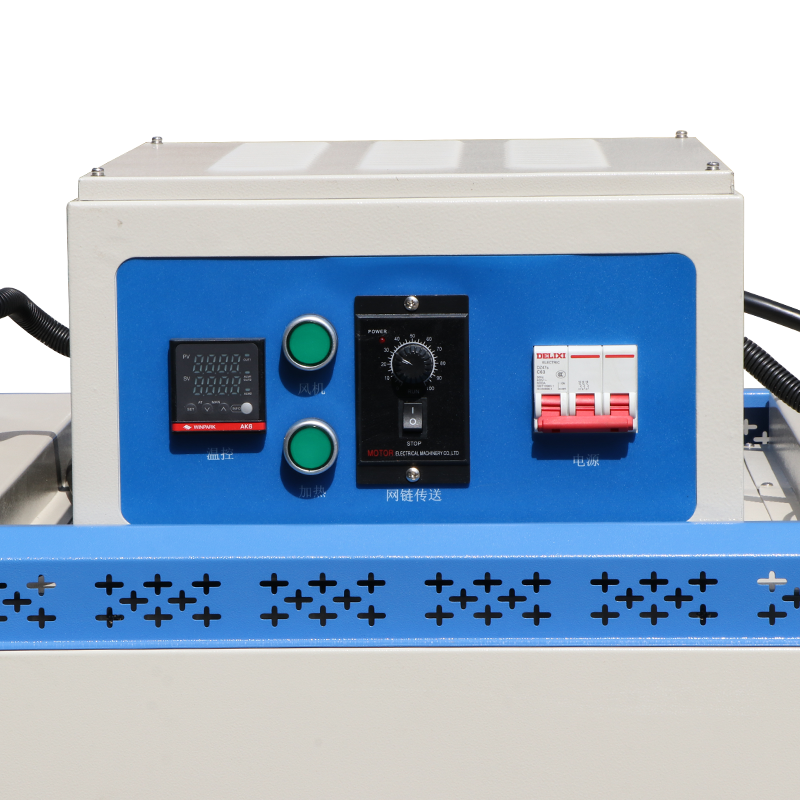

Machine Features:

1. Bottom-Fed Film Structure — Faster Film Replacement

Film loading is more convenient and ergonomic

Greatly reduces downtime and improves continuous production efficiency

Ideal for high-frequency film-changing environments

2. High-Precision Photoelectric Detection

Automatically detects product position with precision (≤ ±1 mm)

Ensures clean sealing and accurate cutting

Seamlessly integrates into fully automatic production lines

3. Optimized for POF Sealing Quality

Supports POF / PE heat shrink films

Specially tuned sealing temperature & pressure for ultra-smooth POF shrink effects

Produces tighter, cleaner, more refined packaging

4. Quick Line Switching & Easy Adjustment

Handwheel adjustment allows format change within 5 minutes

No need to replace mechanical components when switching sizes

Reduces labor intensity and operator skill requirements

5. Energy-Efficient Constant Temperature System

Stable heating avoids energy waste

Ensures consistent shrink quality

Reduces long-term production cost

6. Industrial-Grade Continuous Operation

High-strength structure suitable for 24-hour operation

Low failure rate with long-life components

Reliable for large-volume orders and factory-level production

Products Specification:

| Item | Specification |

| Model | FQ450LX |

| Power Supply | AC 220V, 50/60 Hz |

| Power | 2.2 kW |

| Packaging Speed | 15–25 pcs/min |

| Max Packaging Size | W+H ≤ 400 mm; L+H ≤ 500 mm; H ≤ 150 mm |

| Sealing Knife Size | Horizontal 470 mm × Vertical 570 mm |

| Transport Load | 15–20 kg |

| Applicable Film | POF / PE |

| Conveyor Belt Width | 330 mm |

| Air Pressure | ≥ 0.6 MPa |

| Machine Size | 1700 × 1070 × 1300 mm |

| Machine Weight | Approx. 250 kg |

| Film Feeding Method | Bottom-fed film design |

| Detection System | Photoelectric automatic detection |

| Working Mode | Online shrink packaging, continuous operation |

Products Pictures:

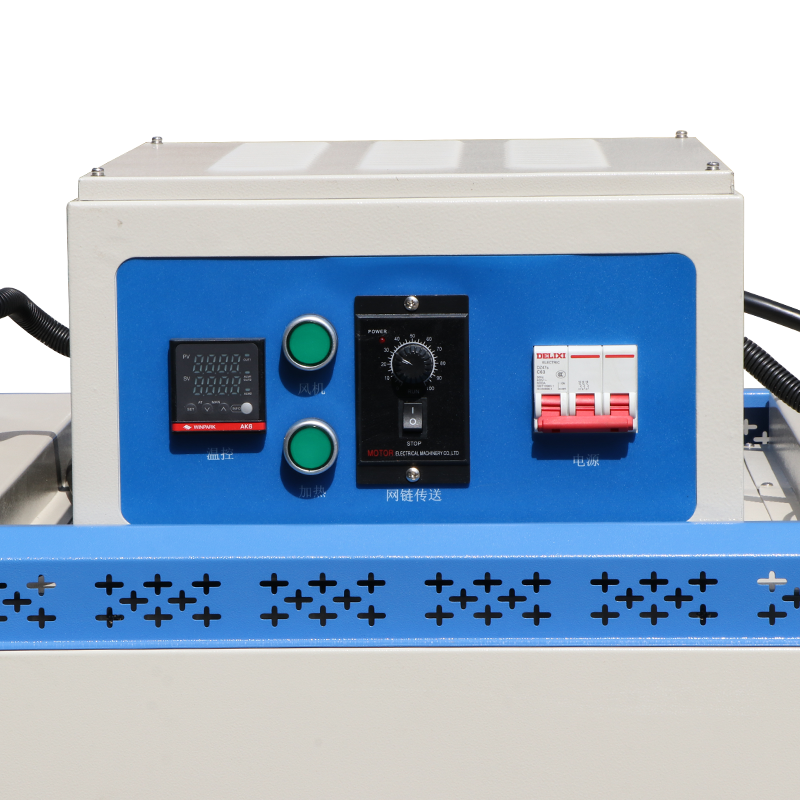

Machine Features:

1. Bottom-Fed Film Structure — Faster Film Replacement

Film loading is more convenient and ergonomic

Greatly reduces downtime and improves continuous production efficiency

Ideal for high-frequency film-changing environments

2. High-Precision Photoelectric Detection

Automatically detects product position with precision (≤ ±1 mm)

Ensures clean sealing and accurate cutting

Seamlessly integrates into fully automatic production lines

3. Optimized for POF Sealing Quality

Supports POF / PE heat shrink films

Specially tuned sealing temperature & pressure for ultra-smooth POF shrink effects

Produces tighter, cleaner, more refined packaging

4. Quick Line Switching & Easy Adjustment

Handwheel adjustment allows format change within 5 minutes

No need to replace mechanical components when switching sizes

Reduces labor intensity and operator skill requirements

5. Energy-Efficient Constant Temperature System

Stable heating avoids energy waste

Ensures consistent shrink quality

Reduces long-term production cost

6. Industrial-Grade Continuous Operation

High-strength structure suitable for 24-hour operation

Low failure rate with long-life components

Reliable for large-volume orders and factory-level production

Products Specification:

| Item | Specification |

| Model | FQ450LX |

| Power Supply | AC 220V, 50/60 Hz |

| Power | 2.2 kW |

| Packaging Speed | 15–25 pcs/min |

| Max Packaging Size | W+H ≤ 400 mm; L+H ≤ 500 mm; H ≤ 150 mm |

| Sealing Knife Size | Horizontal 470 mm × Vertical 570 mm |

| Transport Load | 15–20 kg |

| Applicable Film | POF / PE |

| Conveyor Belt Width | 330 mm |

| Air Pressure | ≥ 0.6 MPa |

| Machine Size | 1700 × 1070 × 1300 mm |

| Machine Weight | Approx. 250 kg |

| Film Feeding Method | Bottom-fed film design |

| Detection System | Photoelectric automatic detection |

| Working Mode | Online shrink packaging, continuous operation |

Products Pictures: