| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

Machine Features:

High-Accuracy Detection

Detects stainless steel as small as Ø0.3mm × 2mm

Identifies metal, glass, ceramic, stone, and dense material contaminants

Advanced AI & Imaging System

Automatic parameter learnin

High-resolution X-ray imaging with defect size measurement

Stores thousands of product profiles (up to 10,000 types)

Powerful Data Management

HACCP-compliant image storage, capacity analysis, and error logs

MTBF/MTTR tracking for maintenance insight

Robust Industrial Design

IP66 waterproof design for easy cleaning

21.5” touch screen for intuitive operation

Stable, high-speed conveyor (up to 75 m/min)

Operational Safety

X-ray leakage < 1 μSv/h

Multi-layer soft curtain protection system

Products Specification:

| Item | Specification |

| Model | 3500D |

| Minimum Detection Capability | Iron: Ø0.3mm × 2mmStainless Steel: Ø0.3mm × 2mmGlass: Ø1.5mmCeramic: Ø1.0mm |

| X-ray Output | 80KV, 210W / 100KV, 150W (optional) |

| Detection Speed | Max. 75 m/min / 43 m/min; Min. 10 m/min |

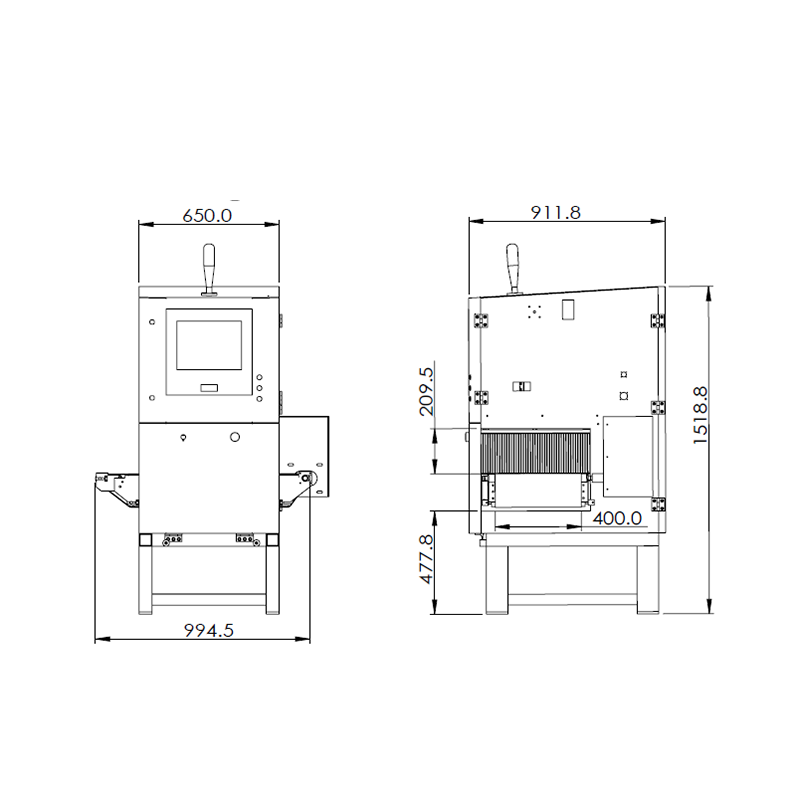

| Conveyor Width | 400mm |

| Max. Passing Height | 225mm |

| Max. Load Weight | 20kg (5kg when speed >40m/min) |

| Belt Height | 750 ± 50mm |

| Industrial Computer | 21.5" Touch Screen |

| Operating System | Windows 10 Professional |

| Defective Image Management | USB storage, HACCP compliant |

| Decorative Functions | 16 modes; up to 10,000 product registrations |

| Product Management | Daily/monthly/model capacity analysis |

| Equipment Management | MTBF, MTTR, error log & analysis |

| Learning Method | Automatic or manual |

| Image Functions | Save/print/analysis (defect size measurement) |

| Waterproof Rating | IP66 |

| X-ray Leakage | < 1μSv/hour |

| Operating Environment | 0°C – 35°C |

| Power Supply | 220V |

| Power Consumption | 1.6 kW |

| Product Weight | Approx. 580kg |

| Dimensions | 1985 × 915 × 1790 mm (H×W×D) |

Products Pictures:

Machine Features:

High-Accuracy Detection

Detects stainless steel as small as Ø0.3mm × 2mm

Identifies metal, glass, ceramic, stone, and dense material contaminants

Advanced AI & Imaging System

Automatic parameter learnin

High-resolution X-ray imaging with defect size measurement

Stores thousands of product profiles (up to 10,000 types)

Powerful Data Management

HACCP-compliant image storage, capacity analysis, and error logs

MTBF/MTTR tracking for maintenance insight

Robust Industrial Design

IP66 waterproof design for easy cleaning

21.5” touch screen for intuitive operation

Stable, high-speed conveyor (up to 75 m/min)

Operational Safety

X-ray leakage < 1 μSv/h

Multi-layer soft curtain protection system

Products Specification:

| Item | Specification |

| Model | 3500D |

| Minimum Detection Capability | Iron: Ø0.3mm × 2mmStainless Steel: Ø0.3mm × 2mmGlass: Ø1.5mmCeramic: Ø1.0mm |

| X-ray Output | 80KV, 210W / 100KV, 150W (optional) |

| Detection Speed | Max. 75 m/min / 43 m/min; Min. 10 m/min |

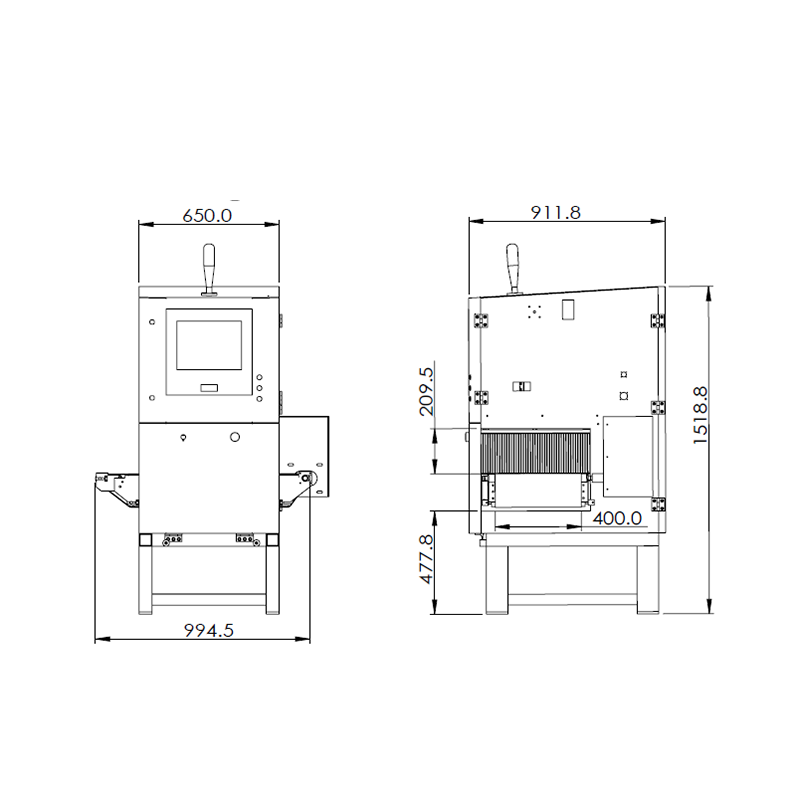

| Conveyor Width | 400mm |

| Max. Passing Height | 225mm |

| Max. Load Weight | 20kg (5kg when speed >40m/min) |

| Belt Height | 750 ± 50mm |

| Industrial Computer | 21.5" Touch Screen |

| Operating System | Windows 10 Professional |

| Defective Image Management | USB storage, HACCP compliant |

| Decorative Functions | 16 modes; up to 10,000 product registrations |

| Product Management | Daily/monthly/model capacity analysis |

| Equipment Management | MTBF, MTTR, error log & analysis |

| Learning Method | Automatic or manual |

| Image Functions | Save/print/analysis (defect size measurement) |

| Waterproof Rating | IP66 |

| X-ray Leakage | < 1μSv/hour |

| Operating Environment | 0°C – 35°C |

| Power Supply | 220V |

| Power Consumption | 1.6 kW |

| Product Weight | Approx. 580kg |

| Dimensions | 1985 × 915 × 1790 mm (H×W×D) |

Products Pictures: