| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

Machine Features:

Energy-Saving Transmission:

Reducer-driven system ensures stable operation with reduced energy consumption.

Double-Sided Beveling Without Flipping:

Allows processing of both upper and lower bevels by rotating the machine head—no need to flip heavy plates.

High Processing Speed:

Maximum beveling speed up to 2.5 m/min significantly improves productivity.

Adjustable Bevel Angle:

25°–45° angle adjustment supports multiple welding edge preparation requirements.

Wide Material Compatibility:

Applicable to V/Y/K/X-type bevels on carbon steel, manganese steel, and aluminum alloy plates.

Broad Industrial Applications:

Ideal for steel structures, pressure vessels, construction machinery, machining, shipbuilding, metallurgy, petrochemical, power towers, and wind power fabrication.

Products Specification:

| Item | Specification |

| Motor Voltage | 380V 50Hz |

| Motor Speed | 1450 r/min |

| Maximum Slope Width | 15 mm |

| Groove Steel Plate Thickness | 9–40 mm |

| Motor Power | 2200 W |

| Width of Groove Travel | 1.5–2.4 m/min |

| Steel Plate Groove Angle | 25°–45° (arbitrary adjustment) |

| Minimum Clamping Plate Width | ≥ 80 mm |

| Machine Dimensions | 800 × 510 × 1070 mm |

| Weight | 250 kg |

| Feed-in Speed | 1.5–2.4 m/min |

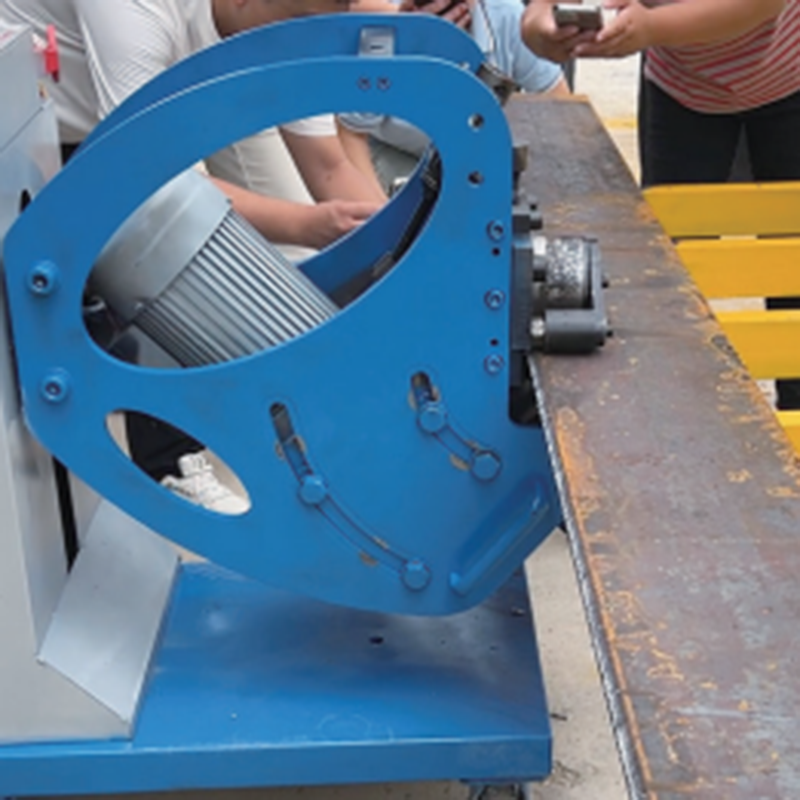

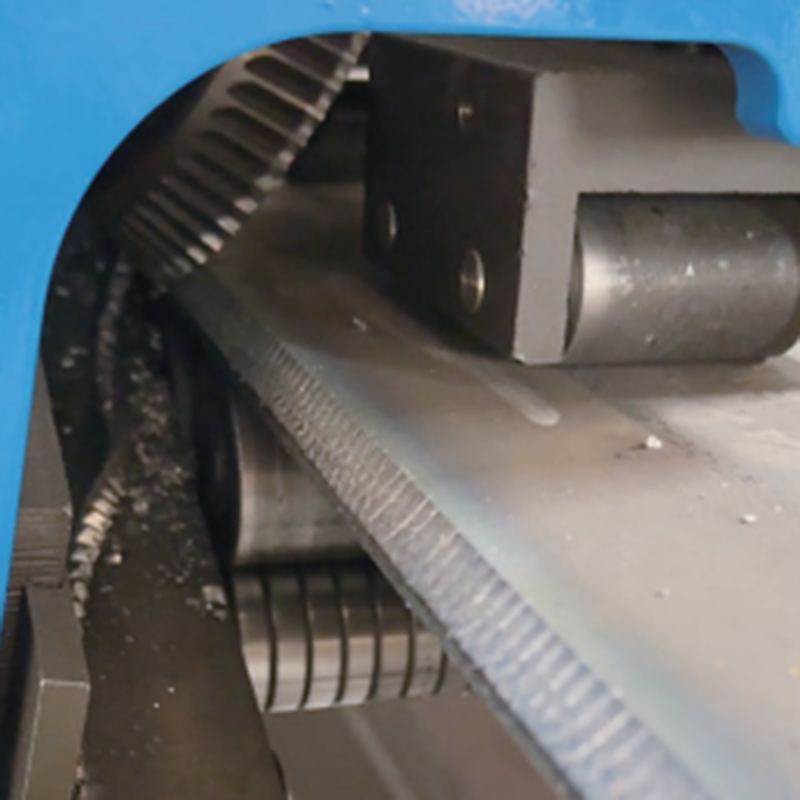

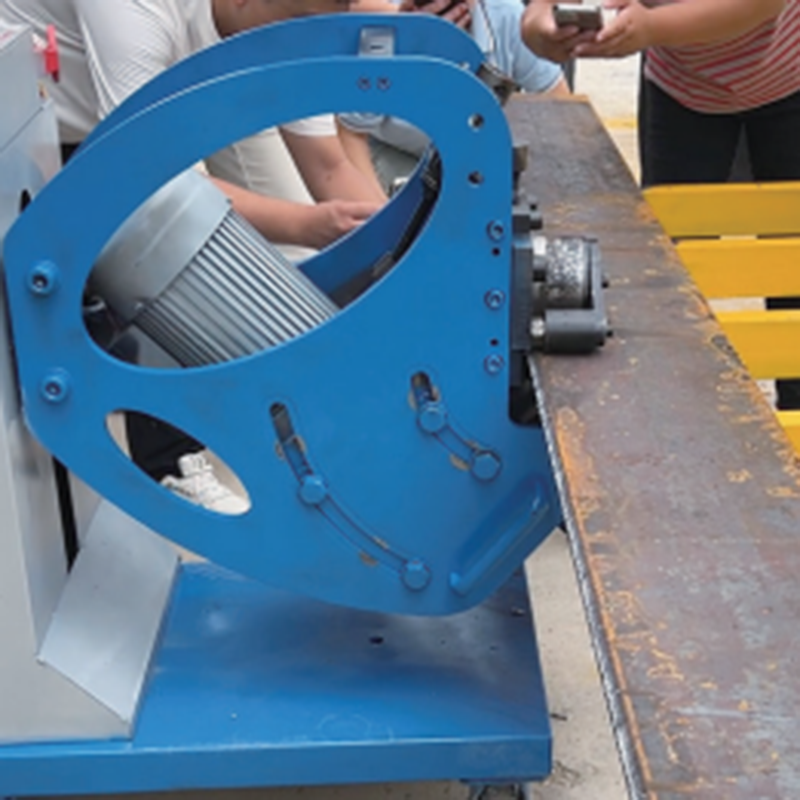

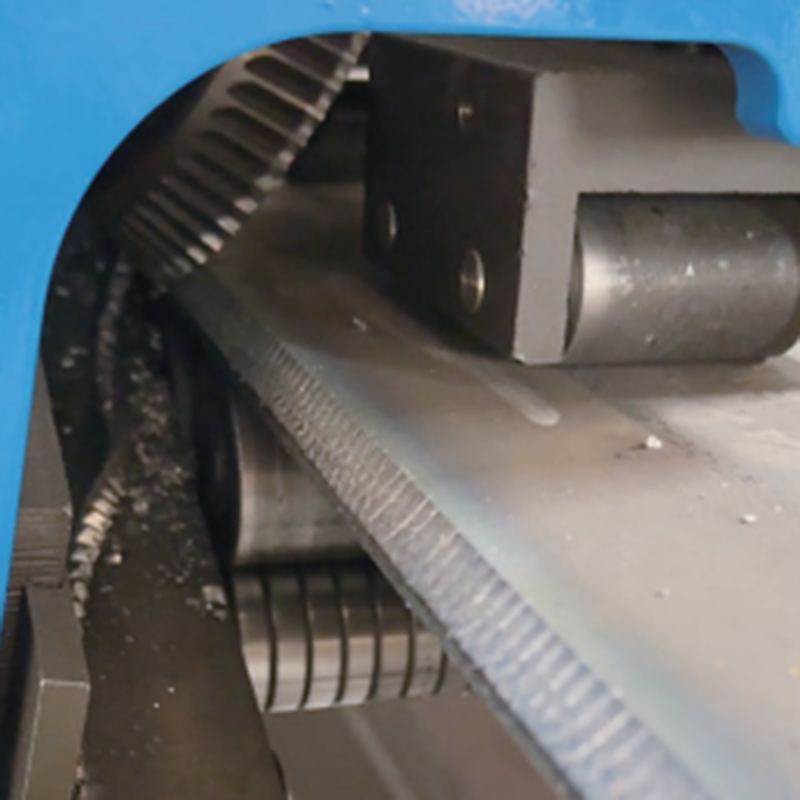

Products Pictures:

Machine Features:

Energy-Saving Transmission:

Reducer-driven system ensures stable operation with reduced energy consumption.

Double-Sided Beveling Without Flipping:

Allows processing of both upper and lower bevels by rotating the machine head—no need to flip heavy plates.

High Processing Speed:

Maximum beveling speed up to 2.5 m/min significantly improves productivity.

Adjustable Bevel Angle:

25°–45° angle adjustment supports multiple welding edge preparation requirements.

Wide Material Compatibility:

Applicable to V/Y/K/X-type bevels on carbon steel, manganese steel, and aluminum alloy plates.

Broad Industrial Applications:

Ideal for steel structures, pressure vessels, construction machinery, machining, shipbuilding, metallurgy, petrochemical, power towers, and wind power fabrication.

Products Specification:

| Item | Specification |

| Motor Voltage | 380V 50Hz |

| Motor Speed | 1450 r/min |

| Maximum Slope Width | 15 mm |

| Groove Steel Plate Thickness | 9–40 mm |

| Motor Power | 2200 W |

| Width of Groove Travel | 1.5–2.4 m/min |

| Steel Plate Groove Angle | 25°–45° (arbitrary adjustment) |

| Minimum Clamping Plate Width | ≥ 80 mm |

| Machine Dimensions | 800 × 510 × 1070 mm |

| Weight | 250 kg |

| Feed-in Speed | 1.5–2.4 m/min |

Products Pictures: